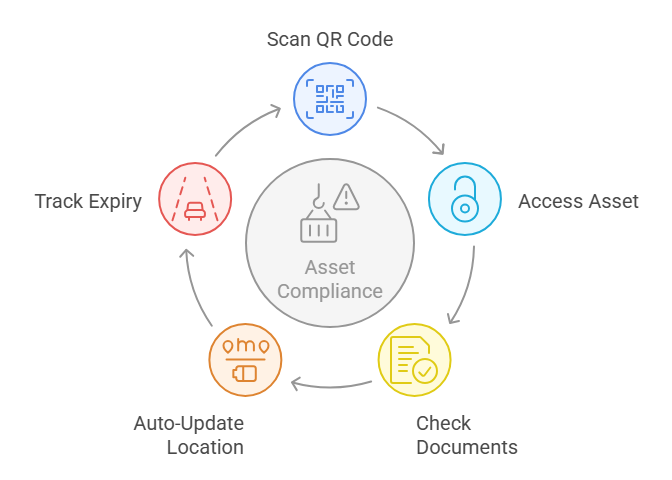

How It Works

One Scan Starts The Whole Process

SafetyMayte is designed to make safety and compliance easy.

- Every piece of your plant & equipment gets its own QR code.

- Attach the QR code to the equipment.

- When an operator or Technician scans it, they’re taken straight to the “live” check-in page.

- No login delays.

- No digging through folders.

- Just tap, complete, submit and go.

Check In With A Few Clicks

The check-in page is built for speed. It opens on any phone, tablet or desktop.

Once scanned, it confirms the operators/technician’s access and checks if they’re close to the job site.

If the GPS doesn’t match, the worker can choose the correct site from a dropdown.

That way, your location data stays accurate without slowing anyone down.

Complete Safety Checklists

After check-in, the operator/technician sees the pre-start “Live Document” checklist.

This includes safety documents like pre-starts, risk assessments, safe work method statements, inductions, and toolbox talks.

Complete the live safety checklists, add any notes, and it’s all saved instantly.

It’s fast, mobile-friendly and matches the individual site requirements.

Forms And Documents In One Place

Once logged in, equipment compliance folders will appear on the screen.

Compliance folders are separated into categories including:

- Live Safety Documentation.

- Insurance Documentation.

- Permits

- Service, Inspection and Commissioning.

Access to documents in the folders is controlled by setting access permissions.

Setting “Permissions” is assigned to the employer or administrative representative.

SafetyMayte uses assigned “Roles” to organise access levels.

Generally, “Roles” with access permission include: (but are adaptable to suit organisational chart responsibilities)

- Employer / Admin – full access to all documents in all folder categories. Full upload capability

- Operator Technician – access to “Live” safety documentation. Upload capability limited to specific service / inspection folders.

- WHS Manager / Site Supervisor – Visual access to folder status for compliance and confirmation. Access to reporting functions.

Status confirmation colours denote:

- Green means compliant.

- Amber means attention required - expiring soon.

- Red means critical or non-compliant.

Live Location & Job Site Matching

SafetyMayte automatically records the asset’s location at check-in.

It checks if that location matches the assigned job site.

If it doesn’t, it prompts the worker to choose or create a new one.

This ensures the equipment’s job site history stays accurate, even when you’re plant is moving locally or across the country.

Track Every Action

Every check-in is saved with a timestamp, asset name, location and user details.

That includes documents completed, forms submitted, and any comments added during the check-in.

Admins and managers can see the full history for any asset on the dashboard.

Summary View For Peace Of Mind

Once the check-in is done, the system shows a compact summary screen.

This gives the user a percentage compliance rating and a clear view of the asset’s document status.

That screen can be exported as a PDF too.

Easy To Update And Maintain

Need to add a new document?

It’s simple. Go to the asset, click upload, choose the compliance folder, and hit save.

You can add an expiry date to trigger visual alerts.

You can also rename or preview documents anytime.

Everything is organised and easy to find.

Works With Any Role

- Operators/technicians can scan and complete safety checklists.

- Site Managers and WHS Reps observe compliance status.

- Employers assign job sites and documents to document categories.

- Admins manage roles, permissions, and system settings.

Critically, permissions can be adapted to mirror different organisational chart responsibilities.

Try The Faster, Smarter, & Safer Way

- Scan the QR code.

- Enter ‘Guest” password

- Take a look

If you’re interested, please get in touch and we’ll walk you through it.